List of PTFE membrane filter companies, manufacturers and suppliers Air & Climate Industrial Ventilation Acid Gas Emissions Control Activated Carbon Air Treatment Activated Carbon Treatment

To ensure maximum corrosion resistance, purity levels and low particle generatation, Yamada pumps feature diaphragms, liquid chambers and manifolds that are machined from 100% virgin PTFE. Polypropylene and High Density Polyethylene are used in the air motor section (non-wetted) to ensure resistance in a corrosive environment.

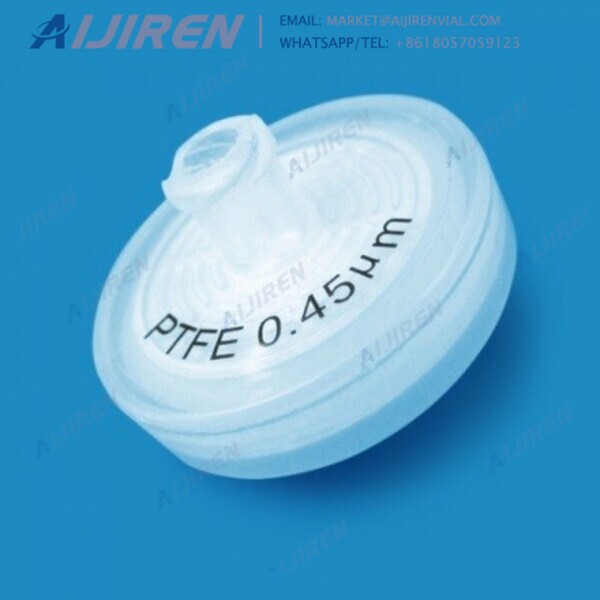

high performance PTFE membrane which is inherently hydrophobic and chemically resistant. This membrane is designed to remove bacteria, viruses and particles from air and gas streams, even in the presence of humidity and moisture. The same membrane

China High Quality Pes Filter Membrane with 022um 1.0um Pore Size, Find details about China High Quality Pes Filter Membrane, Ptfe Filter Membrane from High Quality Pes Filter Membrane with 022um 1.0um Pore Size - Hangzhou Anow Microfiltration Co

2018/6/13 · Amazon Filters reports on the supply of significant quantities of SupaPore TPB PTFE membrane filters to a major pharmaceutical company for off-gas filtration of their large-scale fermenters. In the preparation of vaccines and cultivation of pathogenic microorganisms, the chance of hazardous microorganisms escaping from the fermenter into the environment must be prevented.

Market Overview. The polytetrafluoroethylene (PTFE) membrane is a non-reactive filter media, which is used in a wide range of applications that involve acids, bases, solvents and other liquids. The PTFE membrane market holds abundant opportunities in the industrial applications where factors such as temperature, humidity, dust, mineral production,

Filmedia® is committed to providing first grade filter solution, after years of development, we have established close business relationship with our customers in more than 100 countries and regions in the world. The key to our rapid growth and development comes from our management’s ethos of premium quality, innovation and being customer-focused.

Introduction. MS ® PTFE membrane offer excellent control over pore size, porosity, permeability and thickness.Designed to help deliver precision, accuracy and reliability. MS ® PTFE Materials exemplify the critical design standards required in many challenging

2019/9/27 · 1. For 1 casing with 99 membranes: QR = 1 m3/h/membrane/m/s x 99 membranes x 3.5 m/s = 346.5 m3/h. Using this flow and, to reduce the pressure drop, a circulation speed in the loop of 1.5-2 m/s is taken, then the diameter of the recirculation loop should be 12”.

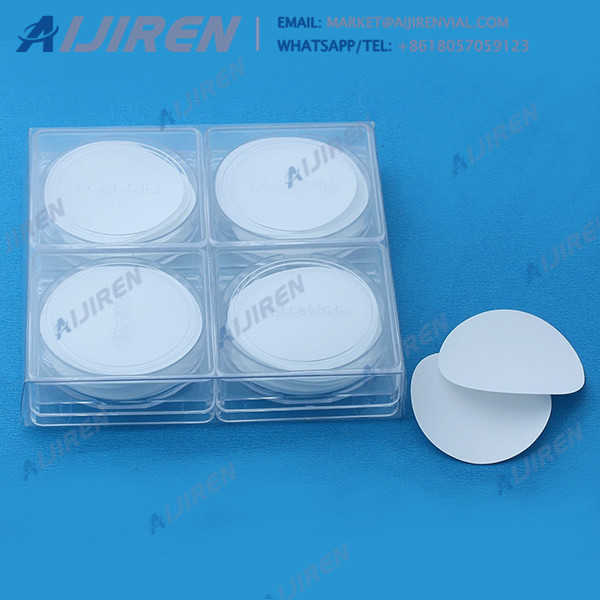

PTFE Membranes. Cytiva's Whatman ™ PTFE membranes are chemically stable and inert. They are suitable for applications involving aggressive organic solvents, strong acids, and alkalis. PTFE membranes are particularly suitable for preparing samples for HPLC analysis. The hydrophobic nature of the membrane also has applications for air and gas

2015/9/16 · The GEMÜ code 5M diaphragm has a two-piece design and consists of a PTFE face and a peroxide-cured EPDM backing. An FKM backing is also available for highly permeating media (GEMÜ code 5F). The PTFE used is a chemically modified second generation PTFE - called PTFE TFMTM. This material offers maximum chemical resistance and also features a