PTFE membrane is a filter that is hydrophobic or hydrophilic in nature and is strongly resistant to solvents, acids, and bases. The membrane is also resistant to high temperatures and is perfect for sampling purposes.

PTFE Membranes. Cytiva's Whatman ™ PTFE membranes are chemically stable and inert. They are suitable for applications involving aggressive organic solvents, strong acids, and alkalis. PTFE membranes are particularly suitable for preparing samples for HPLC analysis. The hydrophobic nature of the membrane also has applications for air and gas

2020/8/1 · PTFE membranes are naturally hydrophobic with excellent chemical resistance, making them the ideal choice for sterile venting of gases, non-aqueous solvents, acids, and aggressive fluids. In the chemical and pharmaceutical industry, PTFE membranes are used in filtration of strong acids and aggressive solutions, venting of gases and phase separations.

2020/4/16 · Barrier Property – The PTFE surface layer becomes the ‘skin’ of the membrane, protecting the membrane from acid, solvent, fats, oils and greases. It also locks in waxes and oils inside of the membrane called plasticizers. Without this layer, liquids can soak into the rubber (typically 1% to 2% for water, varies for solvents).

PTFE membrane filters have an excellent chemical compatibility (pH 1 to 14), so that they are also used for the filtration of solvents and acids, to which other filter types are not resistant. Moreover they can be used to filter aqueous solutions as well, but because of their hydrophobic characteristics, they must be pre-wetted with ethanol or methanol before the filtration of

As hydrophilic PTFE type becomes transparent when wet, it is easy for microscopy. It is not necessary to do hydrophilic treatment which was conducted for PTFE type membranes. A membrane filter which can be used with water or organic solvents

PTFE membranes are naturally hydrophobic with excellent chemical resistance, making them the ideal choice for sterile venting of gases, non-aqueous solvents, acids, and aggressive fluids. In the chemical and pharmaceutical industry, PTFE membranes are used in filtration of strong acids and aggressive solutions, venting of gases and phase separations.

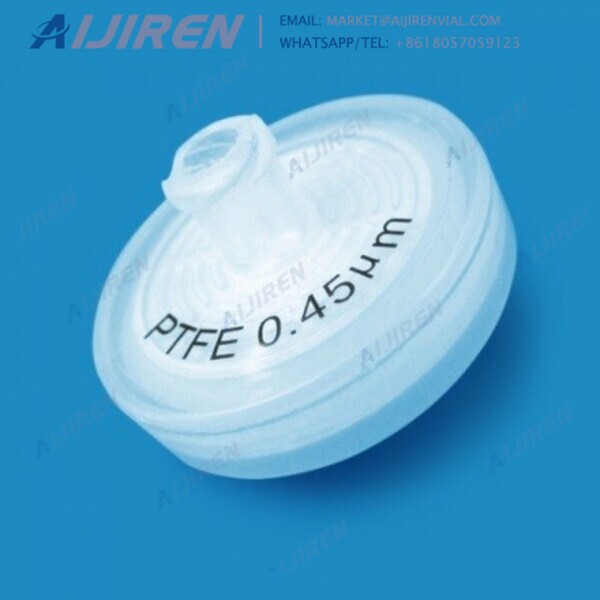

Inside the syringe filter polytetrafluoroethylene is used as membrane material. The hydrophobic PTFE membrane is very resistant towards all kinds of solvents as well as acids and bases. Flushing with alcohol, followed by water, makes the originally hydrophobic membrane more hydrophilic.

The polytetrafluoroethylene (PTFE) membrane is a non-reactive filter media, which is used in a wide range of applications that involve acids, bases, solvents and other liquids. The PTFE membrane market holds abundant opportunities in the industrial applications

The Reason: Sartofluor PTFE membrane and support fleece are extremely hydrophobic and feature optimized pleat density. The Result: effective drainage of condensate and no water blockage. Validated performance for assured security Sartofluor cartridges