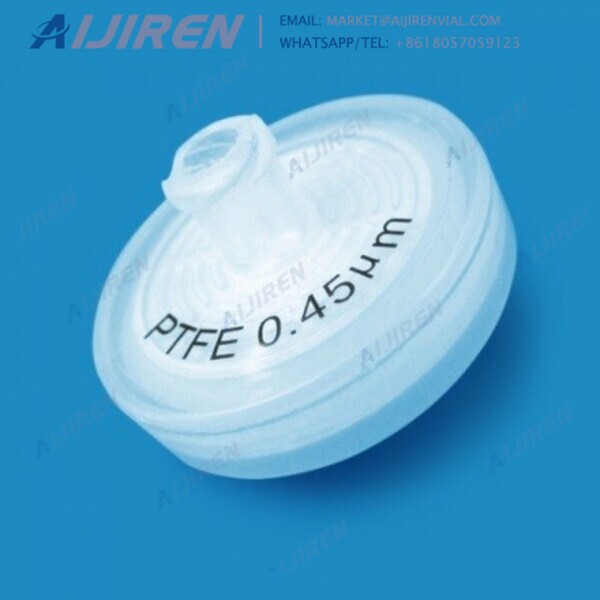

POREX® PTFE Membrane Vents Protective Vents for Electronic Enclosures PTFE membrane vents are used in sealed devices to allow pressure equalization due to temperature changes and minimizes condensation while keeping dust, dirt, and moisture out.

POREX® PTFE Membrane Vents Protective Vents for Electronic Enclosures PTFE membrane vents are used in sealed devices to allow pressure equalization due to temperature changes and minimizes condensation while keeping dust, dirt, and moisture out.

Porex PMV20I is a 0.44mm thick venting disc with 3M 9086 adhesive. It has IP ratings of 64, 65 and 68 and is compliant with RoHS, WEEE and REACH. PMV20 material can be supplied, with or without adhesive, in custom disc sizes, other shapes, sheets and

2021/4/14 · Global PTFE Venting Membrane Market 2020 by Manufacturers, Regions, Type and Application, Forecast to 2025, a new addition to the catalog of MarketQuest.biz, contains a set of essential analyses related to the values as well as existing business scenarios available in

Porex PTFE materials offer excellent control over pore size, porosity, permeability, water intrusion pressure and thickness. Designed to help deliver precision, accuracy and reliability, Porex porous PTFE materials exemplify the critical design standards required in many challenging filtration, venting, diffusion and media support applications.

Its unique composition makes it ideal for protection vents commonly used by the packaging, electrical/automotive, and medical industries. There are two types of porous PTFE: expanded PTFE (or ePTFE), and sintered PTFE (or sPTFE). PorVent® products use POREX sintered PTFE.

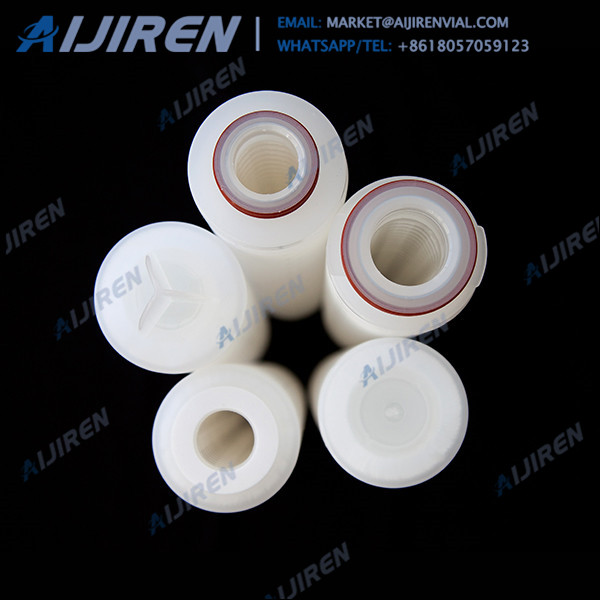

Microporous PTFE Membrane -- POREX®. Optimize your energy storage and generation products by utilizing Porex porous components. With our unique and durable POREX® Virtek™ microporous PTFE membrane, the vent allows for general pressure compensation under normal use, and allows gases to escape rapidly in the event of product failure. With a

Millex Syringe Filter, Fluoropore® PTFE, Hydrophobic, Non-sterile 0.20 µm pore size, 25 mm diameter, Millex-FG hydrophobic PTFE membrane, for gas filtration and venting applications; find Millipore-SLFG02550 MSDS, related peer-reviewed papers, technical

2019/6/29 · Porex suggested use of the Porex Virtek PTFE venting and filtering solution made from the company’s proprietary medical-grade sintered PTFE hydrophobic membrane. The filter consists of particles fused together through heat and pressure and does not require supporting layers (or a scrim), unlike expanded PTFE film.

2020/5/27 · Both the Porex and Oxyphen technologies offer venting material which can be used in the automotive, electronics, healthcare and industrial markets. Developed using a proprietary PTFE sintering process, the Porex Virtek PTFE features an intricate network of open-celled, omni-directional pores that enable critical passage of small molecules such as air and water vapour

Weldable Membranes. Venting membranes made from porous PTFE can be excellently welded on plastic parts, thermally or using ultrasonic technology. Welding enables a highly durable connection between the membrane and the component, even under harshest conditions. The membranes ensure reliable venting and protect the housing against penetrating

DIFFUSION MEDIA SUPPORT FILTRATION VENTING POREX® Porous PTFE Materials Features • Standard pore sizes from 1µ to 50µ (by Bubble Point) • Standard roll width 330mm • Available conversions: sheets, slit rolls, die-cut parts, rotary cut parts and adhesive discs