2011/4/19 · SUTTON, MA--(Marketwire - Apr 19, 2011) - Interstate Specialty Products, Inc. has introduced a line of standard and custom die-cut microporous PTFE membrane

PTFE Microporous membrane pleated filter element. PTFE microporous membrane pleated filter element is made of natural hydrophobic polytetrafluoroethylene (PTFE) membrane and polypropylene material parts by advanced hot-melt sealing technology in a controlled Class-100 clean environment without any adhesive and surfactant, and meets the technical

Data based on 100 um film thickness at 23˚ C. Method : ASTM D1434 for gases. Water vapor according to DIN 53122. PVDF film is made by Westlake Plastics from Kynar® PVDF. AR *Data published in 1980 Kunstsoffe paper entitled Flourocarbon Films

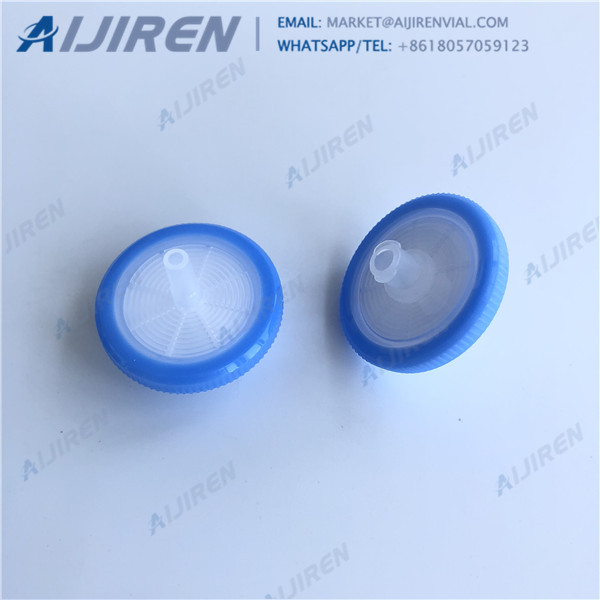

Our unsupported, hydrophobic, PTFE membrane filters are ideal for sterilization and venting applications involving air, gasses, and solvents/acids incompatible with most other filters. Read More These PTFE filters are chemically and biologically inert, stable up to 260°C, and will withstand the majority of concentrated acids and bases and are especially useful for environments that contain

MS ® PTFE membrane media for filtration is made of PTFE (polytetrafluorothylene), and were drawn 2-demension. It is micro-pore film. The PTFE membrane was laminated with great variety of fabric and paper. Applied to extensive industries, including biochemistry, microelectronic, lab material and etc. Directly and indirectly related to pharmacy

2014/9/7 · PTFE (Teflon) • PTFE, or polytetrafluoroethylene, is a Teflon®-coated woven fiberglass membrane that is extremely durable and weather resistant. • The woven fiberglass gives the PTFE fiberglass membrane its mechanical strength.

PTFE membrane filters are naturally hydrophobic with excellent chemical resistance, making them the ideal choice for sterile venting of gases*, non-aqueous solvents, acids, and aggressive fluids. Thin, highly porous membrane filter. Behaves as an absolute retentive membrane. Inert to most agressive solvents, including strong acids and bases.

inherently hydrophobic expanded PTFE membrane validated as sterilizing grade in liquid in accordance with ASTM F838-05. This ensures the removal of all airborne bacteria, viruses and bacteriophage. Features Performance Characteristics Benefits

Improved expanded PTFE materials and improved gasket materials made therefrom, the gaskets being capable of forming a seal with greater bolt load retention than is possible with existing PTFE gaskets. The expanded PTFE membranes of the invention can be

2018/8/3 · The membrane M-E0 without PTFE particles had a relatively low oil flux (1386.5 L m −2 h −1) owing to its dense surface structure with small pores and low porosity. Additionally, with increase of PTFE content, the mean pore size enlarged and porosity got higher which made the transmembrane pressure of oil through the membrane become smaller.

Membrane contactor. Over the last five years, membrane-based degasification has become increasingly popular. Membrane-based degasification uses a microporous hydro-phobic membrane with a pore size on the order of 0.03 µm. Water is passed on one side

Polytetrafluorethylene (PTFE) membranes are naturally and permanently hydrophobic. They are ideal for filtering gases, including humidified air. The extreme chemical resistance of PTFE membranes makes them very useful for filtering solvents or othercals for