PTFE Hydrophilic Membrane Filters, 1.0 um, 90mm, Nonsterile, 100 per pack, SF13852Regular Price $530.68 Price $461.46Add to CartAdd to Wish List.

The advancement in water treatment technology has revolutionized the progress of membrane bioreactor (MBR) technology in the modern era. The large space requirement, low efficiency, and high cost of the traditional activated sludge process have given the necessary space for the MBR system to come into action. The conventional activated

Fluoropore Membrane Filter 1.0 µm pore size, hydrophobic PTFE, 25 mm membrane; Synonyms: Hydrophobic Polytetrafluoroethylene membrane filter discs; find Millipore-FALP02500 MSDS, related peer-reviewed papers, technical documents, similar products & more at Sigma-Aldrich

Unlike hydrophilic filter types, they are not wetted by air humidity. The store will not work correctly in the case when cookies are disabled. Quality Management System DIN ISO 9001:2015 certified 2% online discount costs from €

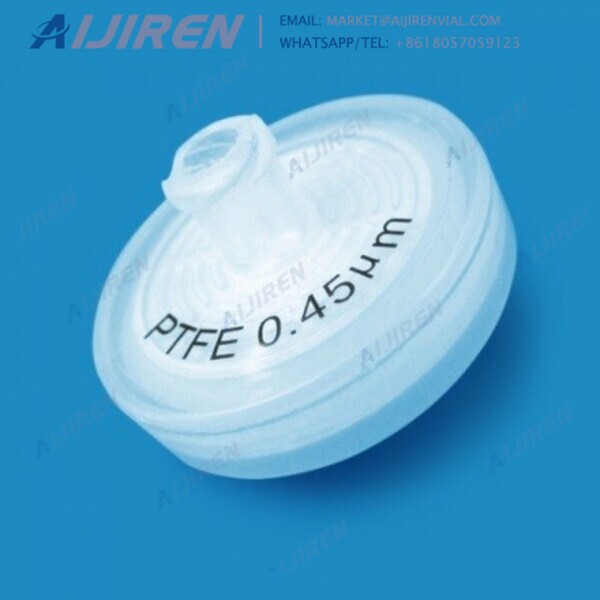

Material: Hardware: PP; Media: PTFE Medium Material: Hydrophilic PTFE Membrane Cartridge Filter: Hydrophilic PTFE Membrane Type: PTFE Membrane Pleated Filter Cartridge Usage: Liquid Filter, Pharmaceutical, Microelectronics, Food & Beverage Filtration Grade: Final Filtration

Fluoropore Membrane Filter 3.0 µm pore size, hydrophobic PTFE, 60 mm membrane - Find MSDS or SDS, a COA, data sheets and more information. Regulatory Expertise Center Find guidance on the latest regulations and standards in the food and beverages industry.

Available in two pore sizes only but multiple diameters, Sartorius’ PA filters will fit that special need every time. Chemically resistant to alkaline solutions. Super for HPLC preparations. Hydrophilic & suitable for sterile filtration of organic solvents. Available in 0.2 μm & 0.45 μm pore sizes and multiple diameters. Shop Now.

A hydrophilic PES membrane can be included in the manufacturing process which allows the filter to be used without pre-wetting; Used for BOE, HF, and TMAH filtration; With a large-scale investment, Cobetter’s manufacturing facility follows Japanese Quality Control Methods and uses advanced German manufacturing equipment to ensure that all

2021年9月30日 · For filter makers, our best-in-class membranes provide many benefits that ensure their reliability in semiconductor and microelectronics processing, like: proven higher liquid flow rate at a given retention level. consistent high quality and repeatable high performance. reliably filters nanometer-level particles and harmful contaminants.