PTFE and other hydrophobic materials are well suited to organic samples and solvents, which result in no resistance or back pressure. However, some organic solvents can absorb into the membrane material, especially when in contact for long periods.

PTFE and other hydrophobic materials are well suited to organic samples and solvents, which result in no resistance or back pressure. However, some organic solvents can absorb into the membrane material, especially when in contact for long periods.

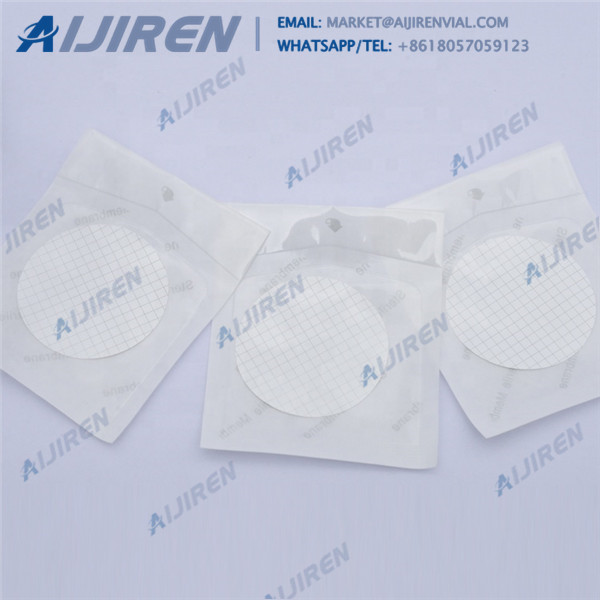

Mitex™ PTFE Membrane is unaffected by almost all liquids, including organic solvents, concentrated acids and bases, propellants, and cryogenic fluids. Mitex™ membrane is unbacked, yet is easy to handle, combining the convenience of a backed membrane with the versatility of a pure PTFE membrane. Mitex™ membrane is hydrophobic.

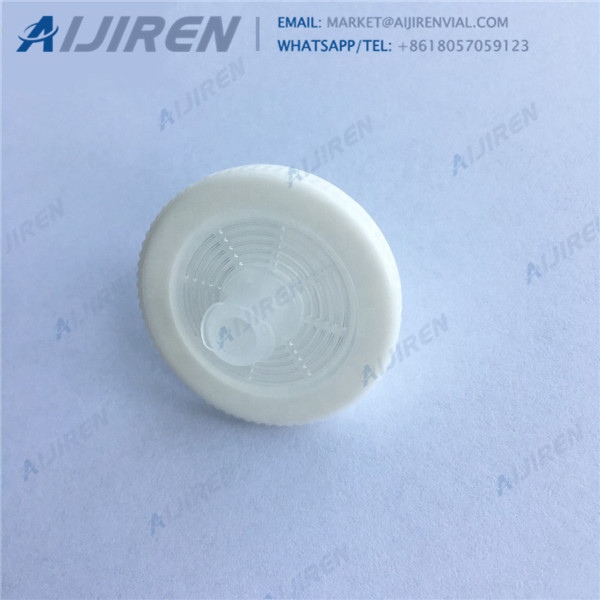

PTFE membrane hydrophilic can also be used with compatible non-aqueous fluids. Vacuum membrane filter 0.45 μm is usually not used for air, gas, or exhaust filtration because if they get wet accidentally, for example through condensation, the filter will block the flow. The hydrophobic PTFE membrane filter disc is modified to obtain a

Sterlitech provides membrane, syringe, capsule filters & custom filter and assembly options for laboratory-scale filtration. Q. What variables affect the performance of a filter? A. Viscosity: The viscosity of a liquid determines its resistance to flow; the higher the viscosity, the lower the flow rate and the higher the differential pressure required to achieve a given flow rate.

MS PTFE membrane media for filtration is made of PTFE (polytetrafluoroethylene), and were drawn 2-demension. It is micro-pore film. The PTFE membrane was laminated with s great variety of fabric and paper. They are new filter media.

Search results for capsule filter ptfe at Sigma-Aldrich Changes will be taking place on SigmaAldrich.com on June 5, 2021 that include visual and functional updates. All registered users will be prompted to reset their password the first time logging in to the new site.

You do solvent filtration if your process stream contains more than 10 wt% solvent. Above this level, the solvent may attack your membrane material. This can lead to a change in retention or even to a total dissolution of your membrane. Depending on your solvent

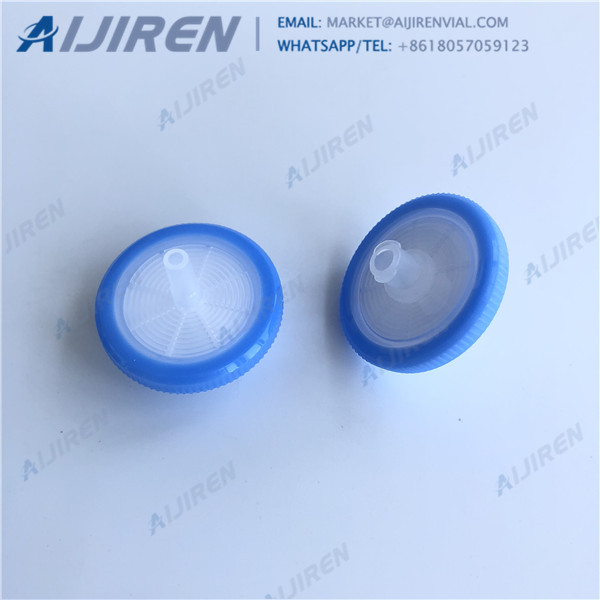

Filter both aqueous and organic solvents Optically clear when wet Hydrophilic PTFE membranes are a thin, unsupported, highly porous film that offers maximum chemical and pH resistance to a broad range of aqueous and organic solvents. This membrane exhibits high flow rates with minimal Related Products: Hydrophilic Ptfe

Fluoropore Membrane Filter 0.22 µm pore size, hydrophobic PTFE, 47 mm membrane; find Millipore-FGLP04700 MSDS, related peer-reviewed papers, technical documents, similar products & more at Sigma-Aldrich. OLIGOS & qPCR PROBES » Order Now Custom

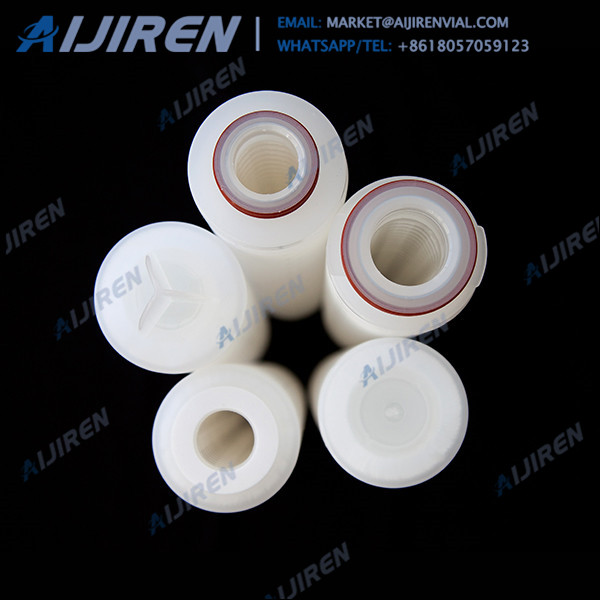

Nalgene 50mm inline filter with PTFE membrane provides an excellent barrier for sterile venting of benchtop fermentors, in-line gas filtration, or protecting vacuum pumps from moisture. It also gives the ability to filter aggressive chemicals, including acids and non-aqueous solvents

Product Description. MS PTFE membrane media for filtration is made of PTFE (polytetrafluoroethylene), and were drawn 2-demension. It is micro-pore film. The PTFE membrane was laminated with s great variety of fabric and paper. They are new filter media. Applied to extensive industries, including pharmacy, biochemistry, microelectronic, and lab

Hydrophilic PTFE membrane is wettable. It can offer superior chemical compatibility, resistant to almost all kinds of solvents. It’s applicable for organic solvents filtration, acids or bases filtration, strong oxidizing solutions, etc. Features and Benefits Superior